Simplicity and user-friendliness are key, and cannot be emphasized plenty of. It has to be probable to discover precise sections/files several years later as well as the provider will have to consider whether or not the composition is reasonable. If It appears sophisticated it ought to be changed until eventually it could be spelled out and described inside a reasonable way.

Conditional approval to proceed to the following qualification stage can be supplied wherever particular acceptance requirements or deviation haven't been completely dealt with and there's a documented assessment that there is no major effect on the next activity.

When all concerns are actually answered, the paperwork can be designed. In the situation of larger sized system jobs, the creation of the learn qualification prepare and traceability matrix is needed within the pursuits of supplying an even better overview. The supplier need to also be experienced (in good time).

Qualification actions whereby areas need to be recognized for placement of knowledge logger or sensors, then schematic layouts to depicts the situation of sensors or site identification shall be laid out in the Qualification/validation protocol for superior clarity.

The C demands do not need a immediate effect on the merchandise high-quality and it is actually a benefit to for every-variety as most of those checks as feasible in the factory. To obtain an effect of system values, merchandise high quality and system capability, these values can be recorded within the manufacturing facility.

, a quarterly journal investigated and edited by a specialist group knowledgeable in all facets of pharmaceutical manufacturing and Command.

Where ever IQ paperwork are compiled by The seller the doc submitted by The seller is evaluated and Any parameters,

For system Regulate, on-line devices is also connected in added locations, as an example, in which water in the purification system enters the Keeping tank together with originally of distribution loops, Each individual locale with advantages and drawbacks in immediacy of contaminant entry consciousness.

The read more assistance supports the necessities of the eu Pharmacopoeia and EU Recommendations to GMP, together with furnishing an indication of the categories of parts prone to be examined in the course of a eu regulatory inspection.

g., water useful for numerous laboratory analyses. Microbial suggestions are presented beneath the informational chapter Water for Pharmaceutical Uses

six. The technique ought to have all the small print of things necessary to Verify calibration and routine maintenance frequency. Re-validation of Purified water System :

The product or service specifications depend upon the water high quality which the system has become designed click here to obtain. The procedure engineer should also have evaluated suited warn and action stages for the procedure, which form The idea for the alarms generated because of the system. When all checks are performed and reviewed, the result of the OQ is offered from the OQ report. If no crucial deviations have been discovered, the PQ can start.

A well-devised QPP, that has been agreed on and signed by both get-togethers, will save time and can make it much easier to accomplish activities which include design, installations and checks. An interface settlement must also be issued early within the venture and may make clear information relating to tie-in points, Command system interfaces and media.

The part which is changed or modified needs to be experienced. Even so, the alternative of one part of the system also influences the other element. Right thought (hazard evaluation) beforehand can reduce the scope in the qualification.

Rick Moranis Then & Now!

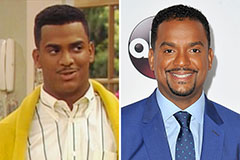

Rick Moranis Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now!